First, equipment overview:

Stirring allows two or more different substances to disperse among one another, resulting in uniform mixing, as well as accelerated heat and mass transfer processes. In industrial production, most of the stirring operations are mechanical agitation, and the main mixing equipment is the medium and low-pressure vertical steel containers. The stirring equipment mainly consists of three parts: stirring device, shaft seal and stirring tank. The role of agitation equipment is as follows: 1 to make the materials mixed uniformly; 2 to make the gas well dispersed in the liquid phase; 3 to make the solid particles (such as catalyst) uniformly suspended in the liquid phase; 4 to make the other liquid phase insoluble Evenly suspended or fully emulsified; 5 enhanced interphase mass transfer (such as absorption, etc.); 6 enhanced heat transfer and other effects. In the selection, according to the actual needs of the material, two or more types of stirrers can be combined to form a composite stirrer to achieve a better stirring effect.

Second, the equipment composition structure:

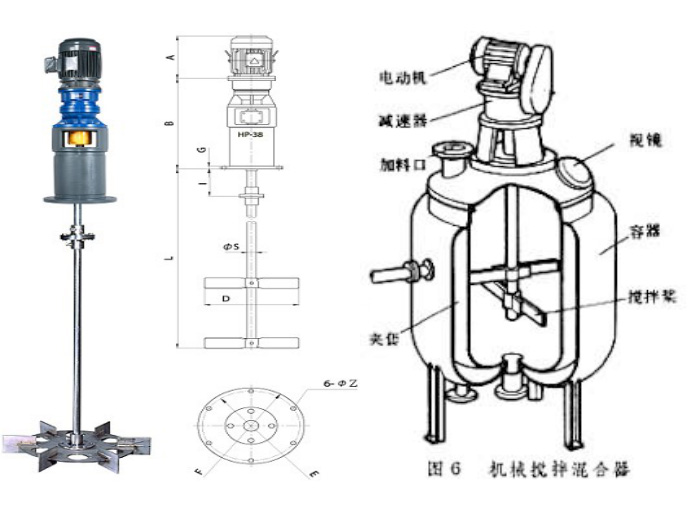

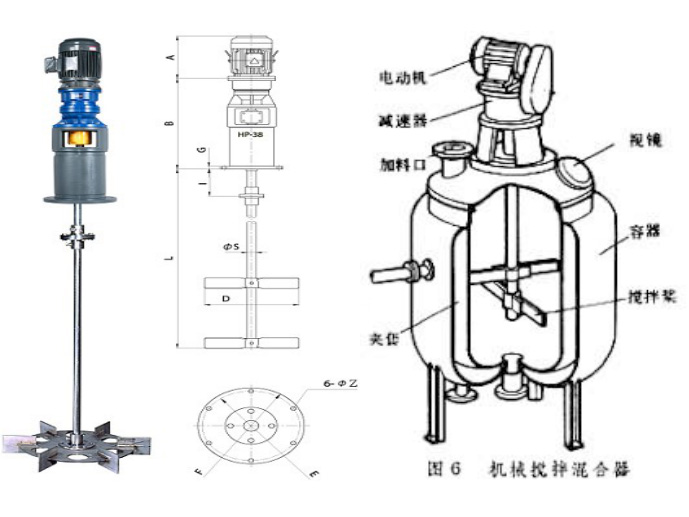

Mainly by the motor, reducer, frame, coupling, stirring shaft, stirrer, internal parts and other components.

1. Motor and reducer: The shape and size of the stirring device are determined according to the mixing purpose and material characteristics of the production scale. The motor and reducer can be used to purchase the brand products such as SEW, etc. according to the requirements of the user.

2. Frame: Stirring shaft should have enough support spacing to ensure that the stirring shaft is not deflected to a large extent, and the transmission output shaft, stirring shaft, and shaft sealing device centering of the transmission are ensured, and sufficient radial and axial bearing capacity is ensured. The main frame has no fulcrum, single fulcrum, double fulcrum and other forms.

3, Couplings: There are mainly fixed, removable and other forms of connection.

4. Shaft seal: If the leakage of liquid is allowed to be high and the pressure in the kettle is low, packing seals may be used; mechanical seals shall be used when there is less leakage allowed, the pressure or vacuum in the kettle is high, and the frictional power consumption between the shaft and bushing is low. Stirring media are highly toxic, flammable, explosive or expensive high-purity materials, or they can be operated under high vacuum conditions with magnetic actuators.

5, stirring shaft: stirring shaft should have sufficient torsional strength and bending strength. Usually, the agitator shaft should have enough rigidity, and the rotation speed should be in the range of 20~800r/min. If the rotation speed is outside this range, the stirring shaft should be considered to have certain flexibility.

6. Stirrer: The purpose of the stirrer is to ensure the effective mixing of materials, consume the least power, the lowest cost, easy to operate and easy to maintain.

7. Stirring internals: mainly baffle baffles (2, 4, 6, and 8 pieces) and special structure of the pipe type.

8, the overall shape of the stirring device: vertical, side-in, oblique, lift, bottom and so on.

Third, stirrer, stirring shaft material:

The material of the stirrer and agitator shaft is mainly selected according to the characteristics of the material. The available materials are: 304, 321, 316, TA, steel-titanium composite, steel-lined plastic, winding fiberglass, and PTFE-lined materials.

Fourth, common stirrer form:

Blender name | Function introduction | Structural classification | Picture structure |

Push type | Typical axial flow paddle for low viscosity fluid mixing, heat transfer, circulation, solids suspension, dissolution, etc. Features: low shear, strong circulation, high speed operation, low energy consumption; stirring speed 20 ~ 500r/min. | Divided into upturned material and downturned material structure, if high-speed operation is required to bring stability. |

|

Turn on the turbine | Axial flow paddle for low viscosity fluid mixing, circulation, solids suspension, dissolution, etc. Features: Medium shear and cycle, medium speed operation, suitable for small and medium-sized equipment; Stirring speed 20 ~ 750r/min. | Three-leaf type, four-leaf type, six-leaf type, split type, curved type, straight type, etc. |

|

Disk Turbine | Typical runoff shear paddles are suitable for mixing, extraction, emulsification, solid suspension, dissolution, bubble dispersion, absorption, etc. of medium and low viscosity fluids; Features: strong shear, medium speed operation, high energy consumption; Stirring speed 100 ~ 600r/min. | Split straight leaves, leaves, curved leaves, oblique leaves, concave leaves. |

|

Box type, anchor type | Suitable for mixing, heat transfer, reaction, etc. of high-viscosity fluids. Operating process; Features: low shear, strong cycle capability, ultra-low speed operation, high energy consumption; stirring speed 60 ~ 120 r/min. | It is divided into elliptical bottom, 90 degree taper, 120 degree cone bottom, anchor type, and special glass anchor structure. |

|

Ribbon type | Suitable for high viscosity and high solid content materials mixing, heat transfer reaction and other operating processes; Features: low shear, strong cycle capacity, ultra-low speed operation, high energy consumption; Stirring speed 30~80 r/min | Double ribbon type, ribbon screw type |

|

Three leaves Sweep | Runner paddle, suitable for mixing, heat transfer, circulation, crystallization, solid dissolution of medium and low viscosity fluids; Features: The distribution of shearing is even, and the circulation flow is generated under the cooperation of the baffle plate, which can be installed at the bottom, operating at medium and low speed, and the stirring speed is 200 to 500 r/min. |

| |

Self-priming | Suitable for gas self-priming and redispersion, can be used for catalytic hydrogenation, oxidation, deep aeration and other gas-liquid mass transfer; self-priming ability, can double gas liquid reaction rate, low shear, high-speed operation, moderate energy consumption ; Mixing speed 600 ~ 1500r/min |

|

Fifth, the scope of use:

1. Widely used in various types of reaction vessels such as metallurgy and food industries.

2. Widely used in the mixing chamber of extraction box in various industries.

Six, stirring device picture: