First, the scope of application

In order to meet the needs of customers in different industries, the company launched a multi-process evaporator combination, according to the customer's material characteristics and process requirements, using a combination of multiple processes to combine the advantages of various evaporators, making the evaporation process more reasonable.

Second, the main features

1. Suitable for a variety of crystallization methods;

2. The advantages of evaporators such as rising or falling film are retained;

3. Fouling in the tubes is reduced to a minimum;

4. The use of forced circulation evaporator to avoid the clogging of the material;

5. Combination evaporator can use MVR form, energy saving and environmental protection.

Third, the working principle

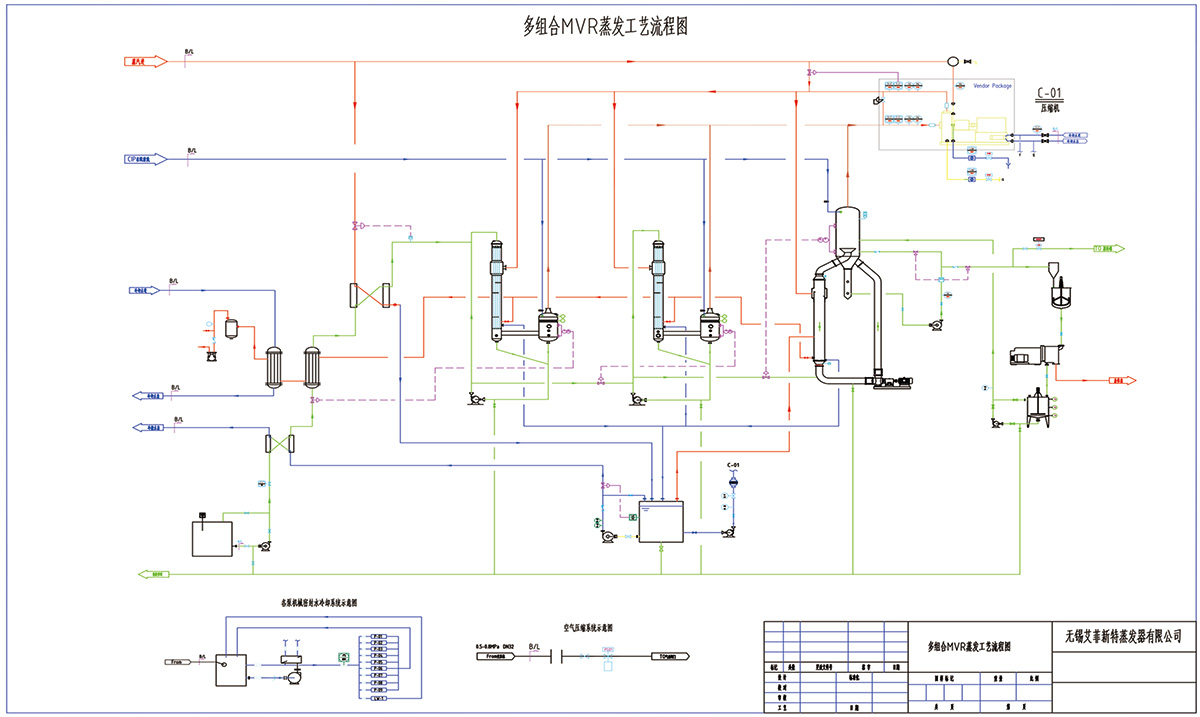

With this combination of evaporation methods, the respective advantages of rising film evaporation, falling film evaporation, and forced circulation evaporator are organically combined. The use of this evaporation process breaks down the limitations of a single evaporation process and reduces energy consumption while broadening the scope of use of the evaporator. Using a multi-process evaporator, the feed liquid is concentrated in a rising film (falling film) evaporator to a certain concentration and then enters a forced circulation evaporator for reconcentration. Finally, it enters the crystallizer and the qualified product is separated from the crystallizer.

Theoretically, multi-process evaporators are not limited to film-up, film-falling, and forced-cycle evaporators. Instead, they select the most appropriate process equipment from various types of evaporative enrichment equipment according to the nature of the material and the conditions for evaporation. A combined evaporator system is formed to achieve optimal treatment results.

Fourth, process flow chart: