First, the working principle:

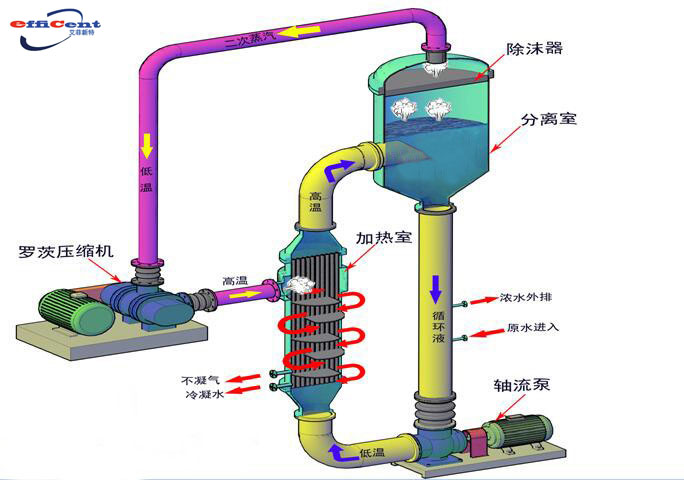

The main principle of MVR evaporator (mechanical steam recompression) is that the secondary steam generated during the evaporation process of the material solution is compressed by the compressor and the pressure and temperature of the secondary steam increase, the heat enthalpy increases, and the secondary compression occurs. The steam is sent to the heating chamber of the evaporator again as heating steam, so that the liquid is kept boiling, and the heating steam itself will condense into water, so that the original steam to be condensed is fully utilized, and the heat is recovered. Heat increases the thermal efficiency and drastically reduces the energy consumption of the evaporation process.

Second, the composition of the MVR evaporator system:

Mainly by the preheater, heater, separator, compressor, vacuum system, pump, operating platform, electrical instrument control cabinet and valves, piping and other systems, the system structure is relatively simple, easy maintenance.

1. Preheater: In most cases, the solution to be evaporated needs to be warmed up before entering the evaporator.

2. Evaporator: The solution that needs to be evaporated is heated in the evaporator and the heat source steam to generate evaporation. Different types of evaporators are selected according to the nature of the different solutions.

3. Separator: For the separation of steam and liquid, different separators can be selected according to the nature of different solutions. There are generally centrifugal separators, gravity separators or separators with special structures.

4. Vacuum system: Maintain the vacuum degree of the whole system, and withdraw some air, non-condensing gas and gas brought in by the solution from the device to achieve the stable evaporation state of the system.

5, pump: transport the solution to be evaporated and the concentrated solution. According to the different nature of the solution to choose different types of pumps, centrifugal pumps, positive displacement pumps, and screw pumps can generally be used.

6. Compressor: Providing evaporation heat source by compressing secondary steam to increase the heat of secondary steam. According to the requirements of different flow rates and compression ratios, a variety of compressors can be selected. For materials with particularly large temperature rise, multi-stage compressors are used in series to meet the requirements of temperature rise.

7, the control system: MVR evaporation system control center, through the motor motor speed adjustment, valves, flow meters, temperature, pressure control, in order to achieve automatic evaporation, cleaning, shutdown and other operations. Automatic alarm, automatic protection system from damage, keep the system dynamic balance.

8. CIP cleaning system: scaling of different solutions may occur after a period of time. You can use CIP in-situ cleaning or mechanical cleaning.

Third, the main features:

1. MVR energy-saving evaporator technology is currently the most advanced evaporator technology in the world, requiring only a small amount of steam (a small amount of raw steam is needed during start-up, and almost no steam is needed during normal operation), which greatly reduces the operation of the company. Cost, reduce environmental pollution.

2. As the compressor is used to provide the heat source, the temperature difference in the evaporation process is small compared with the conventional evaporator, and the evaporation can be achieved mildly, which greatly improves the product quality and reduces the fouling.

3, no condenser or only a small area of the condenser, the structure and process is very simple, fully automatic operation, continuous operation, safe and reliable.

4, the device is equipped with CIP cleaning pipeline, can achieve online cleaning, the entire set of equipment is easy to operate, no dead ends.

5, low operating costs, low energy consumption, operating costs is 1/3-1/4 of the operating cost of an ordinary three-effect evaporation system.

6, the system covers an area of small, fewer personnel; supporting public works projects less

7. Applicable scope: Mechanical vapor recompression (MVR) evaporator, suitable for process wastewater treatment, electroplating wastewater treatment, copper sulphate, nickel sulphate evaporation crystallization, glucose, organic acid, VC, xylose, pharmaceutical, chemical, biological Evaporation, concentration and crystallization of industries such as engineering, environmental engineering, waste liquid recycling, papermaking, and salt manufacturing.

Four, MVR evaporation system process schematic

Fives、System equipment scene picture