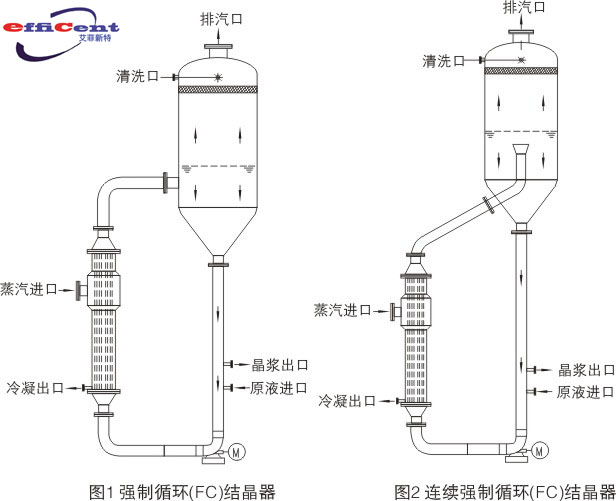

1、Forced circulation crystallizer

The forced circulation crystallizer can be either single-effect or multi-effect, or it can be steam recompression (thermodynamic TVR or mechanical NVR). The operating point of the forced circulation crystallizer can be from low vacuum to atmospheric pressure. Usually these devices are often used where high evaporation rates are not essential for crystal size or where the crystal growth rate is generally required.

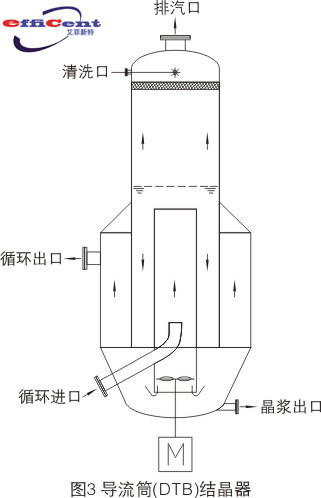

2、Draft tube baffle crystallizer

The draft tube (DTB) crystallizer is a mixed suspension product discharge (MSMPR) design that is suitable for vacuum cooling crystallization and has a stable evaporation rate. Such a design is used in applications where heating (or a small amount of heating) is not required, and it can be designed to be a compact device with a low investment.

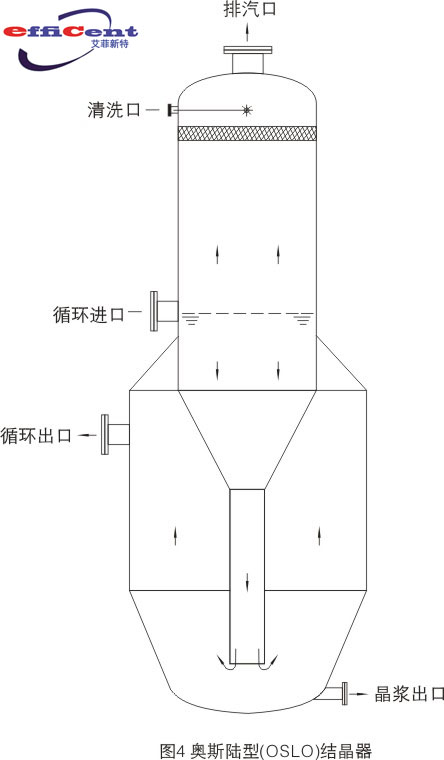

3、Oslo type crystallizer

Oslo-type (OSLO) crystallizers are also known as suspended bed crystallizers. Oslo-type (OSLO) crystallizers have been designed and used for a long time and have a wide range of applications for obtaining large-grain crystals.