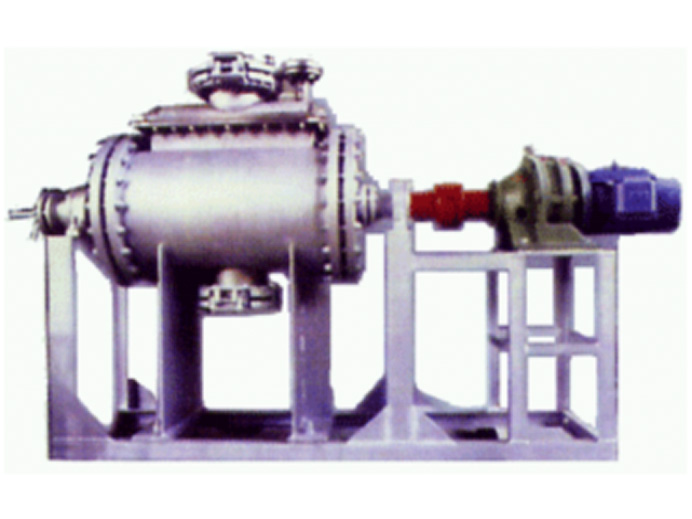

First, equipment overview:

The horizontal high-efficiency cooling crystallization machine is equipped with a hollow shaft and a plurality of multi-layer cooling coils and a scraping wall stirring mechanism which are rotated together with the hollow shaft in a horizontal cylinder with a cooling jacket, and has a very large cooling area. The characteristics of large output. The internal structure is in a horizontal jacketed segmented elongated cylinder, with multiple sets of continuous spiral cooling coils with different inner and outer diameters and different lead, and spiral cooling discs on the outermost layer. A continuous scraper wall type spiral thrust device with a small clearance gap between the inner cylinder and the crystallization machine is installed on the pipe, and a plurality of continuous spiral cooling coil pipes and a scraped wall type continuous spiral thrust device are slowly rotated and driven by a speed-regulating drive device. The material is added from the left feed end and continuously crystallized while cooling the tube jacket and multiple sets of continuous spiral cooling coils. The crystals are slowly pushed by the continuous screw pushing device to the outside of the right discharge end to push out the whole crystal. The process is fully automated under PLC or DCS control

Second, the composition of the device structure:

Mainly consists of inner cooling turntable, outer jacket (or outer coil), transmission motor, speed reducer, coupling, discharge device, rotary joint, main body of equipment, rotary joint, operation platform, various process interfaces, control system, etc. .

Third, the characteristics of the equipment:

1. The power consumption of the horizontal crystallizer is only about 1/7 that of the enamel reactor with the same output.

2. The industrial crystallization process should avoid spontaneous nucleation to ensure that the average crystal size of the crystalline product is large. Only by controlling the crystallization in the metastable zone can this goal be achieved. The intelligent crystallizer increases the cooling area due to the addition of an inner disk that rotates with the shaft. The stirring effect is good, the heat transfer coefficient is high, the temperature of the material in the crystallization machine is uniform, and intelligent control is used to ensure that the crystallization temperature tracks the crystallization curve. The crystallization process is crystallized in the metastable zone, the grain growth rate is uniform, and crystal grains having a narrow grain size distribution and large crystals are easily obtained. In addition, since the cooling heat exchange surface is in the metastable zone, no nucleus is formed spontaneously, the crystallization is performed only on the seed crystals added, and it cannot be grown on the wall surface, so that the cooling surface can be prevented from scabbing.

3. Due to the uniform perturbation of the crystallization process and the low perturbation intensity of the crystallization, the purity of crystals can be made high and the product quality is good. Through the panning system, a more uniform product can be obtained.

4, using open type transmission structure, high efficiency, low energy consumption, easy sealing, no leakage.

5, low speed, reliable operation, less failure, less maintenance.

6. The cooling coil rotates slowly. At the same time, the inner wall of the jacket is provided with a spiral ribbon cleaning device. The heat exchange with the liquid is performed in a dynamic manner. The crystal grains are not easily adhered on the cooling surface, and the fouling of the materials is avoided.

7. Since the crystallization machine is made of stainless steel, compared with the enamel kettle, the enamel will not come off easily, causing the entire enamel kettle to be scrapped, resulting in a great economic loss.

8, the entire process for continuous automatic operation, can be large-scale continuous production.

9. The entire cooling crystal cylinder is set on a bracket whose inclination can be adjusted, so as to control the residence time of the crystal material in the machine and achieve an ideal crystallization effect.

10. The barrel jacket and multiple sets of continuous spiral cooling coils cool and crystallize the material at the same time. The cooling area is large, which greatly improves the crystallization rate.

11. Since multiple sets of continuous spiral cooling coils are cooled and crystallized in a rotating dynamic state, the crystals are not easily attached to the heat transfer surface, and the slow rotation of the propeller type screw device contributes to the clean wall of the inner wall of the cooling tube, thereby greatly improving the Cooling efficiency and crystallization rate, realizing efficient and rapid crystallization.

12, through PLC or DCS control, automatic operation.

13, with real-time and historical records, easy data analysis. The main shaft adopts the frequency conversion speed-regulating device, and the spindle speed is infinitely adjustable, so that the stirring intensity is more suitable for the needs of the crystallization process, so that the resulting crystal grains are more uniform. Fourth, specifications, models and technical parameters and scope of application:

1. Cooling medium: cooling water, deep cold water, frozen brine, etc.;

2, atmospheric pressure crystallization, vacuum crystallization or pressure crystallization can be;

3, to adapt to the material: all kinds of crystals need to cool the pharmaceutical, chemical and other materials, the entire operation process can be carried out in a closed state, especially suitable for continuous crystallization of flammable, explosive, toxic or highly toxic materials and copper sulfate, nickel sulfate Crystallization of the solution;

4. The main series of crystallizer specifications and parameters are shown in the following table;

Project\Model | WPJ-0.2 | WPJ-0.5 | WPJ-0.8 | WPJ-1.0 | WPJ-1.5 | WPJ-2.0 | WPJ-3.0 | WPJ-5.0 |

Full volume (M3) | 0.2 | 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0 | 5.0 |

Cooling area (M2) | 4.1~55 | |||||||

Crystallization | Atmospheric crystallization or pressure crystallization | |||||||

Motor Power (Kw) | According to the nature of the material, it can be selected in the range of 1.1 ~ 22Kw | |||||||

Dimensions (mm) | φ800x2600 | φ1000x3100 | φ1000x3580 | φ1200x3800 | φ1400x4180 | φ1500x4300 | φ1800x4600 | φ2000x5580 |

Materials | Carbon steel, stainless steel, titanium, Hastelloy or composites, etc. | |||||||

weight(T) | 1.52 | 1.98 | 2.78 | 3.46 | 4.32 | 5.46 | 7.62 | 10.85 |

other | According to user requirements, it can produce 0.1~30M3 various specifications of equipment | |||||||